Approvals

SIN-numbers

- Datasheet (in English)

- Distribution Patterns: Conventional

- Distribution Patterns: Pendent

- Distribution Patterns: Upright

- Distribution Patterns: HSW

- Distribution Patterns: VSW

Description

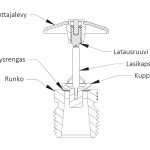

Reliable Models F1FR-series Sprinklers are quick response sprinklers which combine the durability of a standard sprinkler with the attractive low profile of a decorative sprinkler. The Models F1FR-series Recessed automatic sprinklers utilize a 3.0 mm frangible glass bulb. These sprinklers have demonstrated response times in laboratory tests which are five to ten times faster than standard response sprinklers. This quick response enables the Model F1FR-series sprinklers to apply water to a fire much faster than standard sprinklers of the same temperature rating. The glass bulb consists of an accurately controlled amount of special fluid hermetically sealed inside a precisely manufactured glass capsule. This glass bulb is specially constructed to provide fast thermal response. At normal temperatures, the glass bulb contains the fluid in both the liquid and vapor phases. The vapor phase can be seen as a small bubble. As heat is applied, the liquid expands, forcing the bubble smaller and smaller as the liquid pressure increases. Continued heating forces the liquid to push out against the bulb, causing the glass to shatter, opening the waterway and allowing the deflector to distribute the discharging water.

Installation

Sprinklers have orange capsule protectors(or hidden model protective cap) to protect the glass capsule during transportation, handling and installation. The glass capsule protector is removed after installation. Removing protection prematurely may expose the sprinkler damage. Capsule protector is removed by opening them by hand. Avoid using the tools, so do not damage the glass capsule.

Sprinklers must be installed in by the purpose-designed Reliable nozzle wrench. The right key types can be found in the data sheet. Tight connection is obtained by tightening the sprinkler torque of 11-24 Nm. Do not tighten the sprinklers above the recommended torque. The documented higher torque will not improve sealing, it can in fact cause leaks and damage the sprinkler.

Models

F1FR56 (K=80)

Standard Upright

Standard Pendent

Conventional

Vertical Sidewall

Horizontal Sidewall

F1FR56 Concealed (hidden)

Standard Pendent (used with model CCP-cover plate)

F1FR42 (K=60) & F1FR28 (K=40)

Standard Upright

Standard Pendent

F1FR56LL & F1FR42LL Low Lead*

Standard Pendent

*Includes less than 0.25% Lead Content

Listing & Approvals

1. Underwriters Laboratories Inc. and Certified for Canada (cULus).

2. Factory Mutual Approvals (FM)

3. Loss Prevention Council (LPCB, UK)

4. VdS Schadenverhütung GmbH

5. NSF Certified to NSF/ANSi Standard 61 Annex G

6. EC Certificate: 0786-CPD-40239 (RA1414), 0786- CPD-40251 (RA1425), 0786-CPD-40252 (RA1475)

UL Listing Category

Sprinklers, Automatic & Open (VNIV)

Quick Response Sprinkler

| Model | K-value | Response | Thread size | Max.working pressure | Min.working pressure |

| F1FR56 | 80 | Quick Response | ½” NPT | 12 bar | 0,5 bar |

| **F1FR56LL | |||||

| F1FR42 | 60 | Quick Response | ½” NPT | 12 bar | 0,5 bar |

| **F1FR42LL | |||||

| F1FR28 | 40 | Quick Response | ½” NPT | 12 bar | 0,5 bar |

** Low Lead Sprinklers available only with Temperature Rating 200°F/93°C

| Frame | Deflector | Load Screw | Cup | Washer | Bulb |

| DZR Brass QM Brass ***Low Lead Brass |

CDA 260, CDA 220 or CDA 510 |

CDA 360 or CDA 544 |

CDA 651 or CDA 693 |

Nickel Alloy 440 or 360 PTFE Adhesive Tape |

Glass |

| Sprinkler temp. | Max.ambient temp. | Bulb color |

| 57ºC | 38ºC | Orange |

| 68ºC | 38ºC | Red |

| 79ºC | 66ºC | Yellow |

| 93ºC | 66ºC | Green |

| 141ºC | 107ºC | Blue |